* All prices are orientative and may vary depending on distributors, countries, and market conditions.

Description

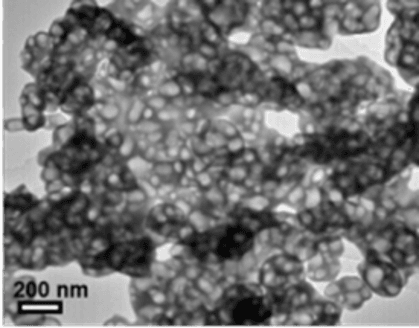

The eHy-1002 is a porous IrO₂ anode catalyst for PEM water electrolysis. It targets the limitations of conventional rutile IrO₂ by combining a highly regular, layered porous morphology with about 74% porosity, which increases exposure of active iridium edge sites and improves mass transfer, charge transfer, and intrinsic OER activity. The bulk iridium content is reduced to approximately 70 wt%, lowering dependence on this precious metal.

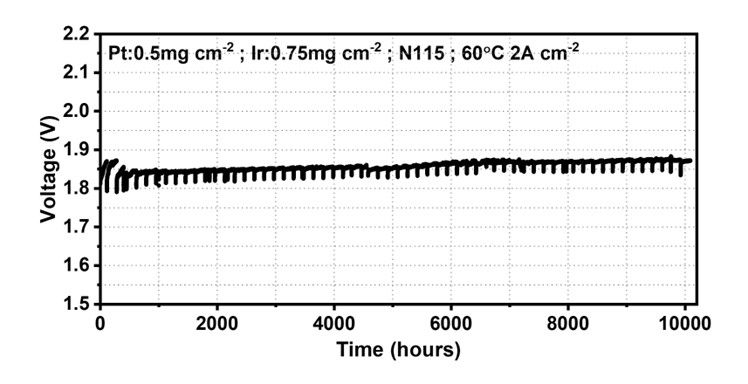

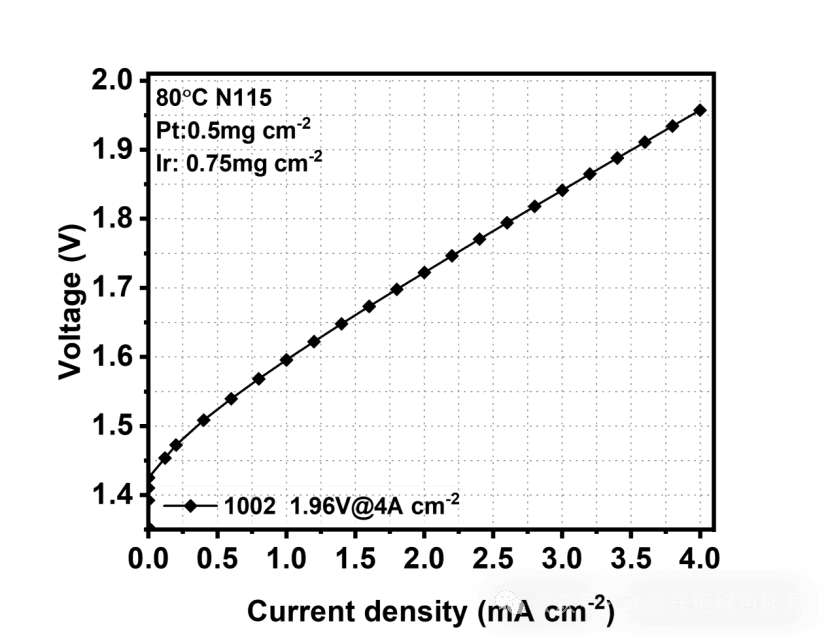

At an MEA iridium loading of 0.75 mg/cm², the catalyst delivers 1.96 V at 4 A/cm² using Nafion N115 at 80°C, and shows long-term stability with more than 15,000 hours of operation and a voltage rise below 3 μV per hour. Additional durability data include single-cell stability beyond 10,000 hours at 1–2 A/cm² and stack stability beyond 1,500 hours at 1.5 A/cm². The product has undergone multiple customer validations, with current production capacity around 600 g per day. For key accounts, the company provides catalyst slurry formulation and coating process guidance.

Price: On request

Specifications

Electrocatalysts

| Mass fraction (%) | ≈ 70% |

| Grain size (nm) | 70 - 100 nm |

| Recommended load capacity (CCM) | 0.75 mg/cm2 |

| Performance | 1.96V@4A /cm² |

| Attenuation rate | < 5μV/ hr@2A /cm² |

| Stability tests | Single pool stable operation of 10000+ hr@1A /cm2&2A/cm², Stable operation of a standard square fuel cell stack 1500+ hr@1.5A /cm² |

| Catalyst Material |

Request Quote / Info

Your request will be sent to Momenta Energy via email.