* All prices are orientative and may vary depending on distributors, countries, and market conditions.

Description

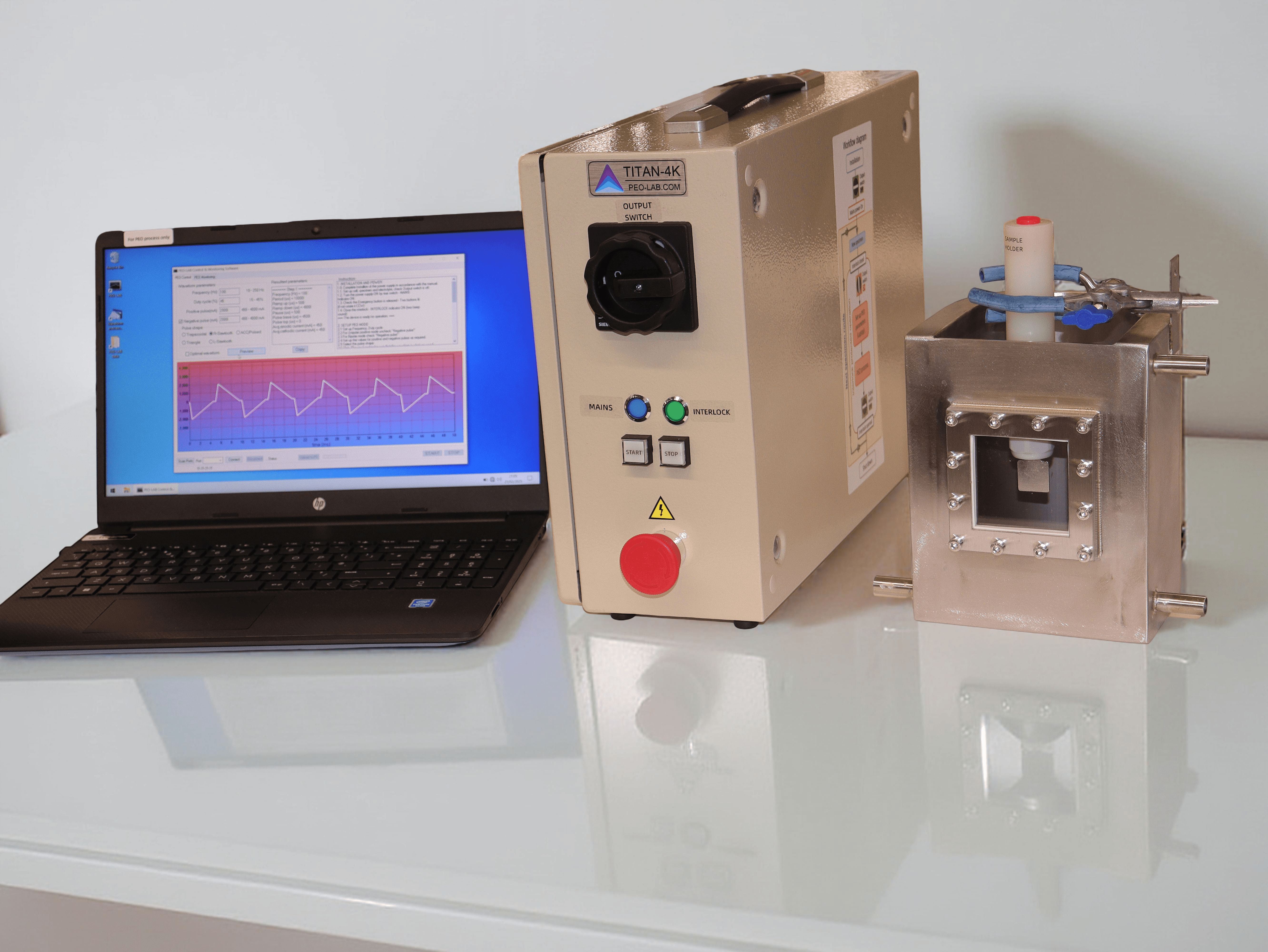

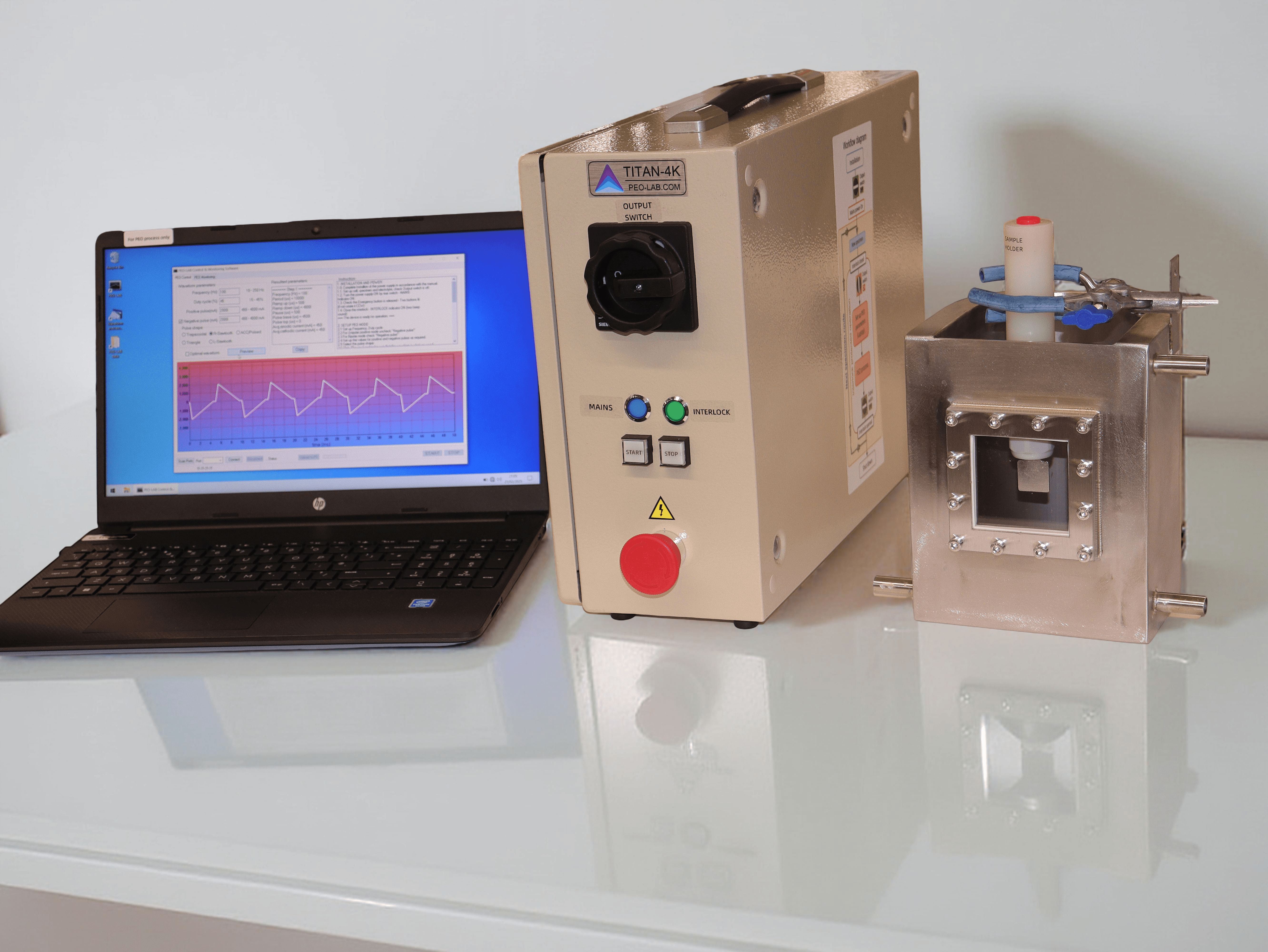

The Starter Kit for Plasma Electrolytic Oxidation (PEO) is designed to support education and research in high-voltage surface engineering. It provides all essential equipment for establishing a laboratory-scale PEO coating facility, enabling students and researchers to learn the fundamentals and conduct PEO studies with a fully integrated, ready-to-use setup.

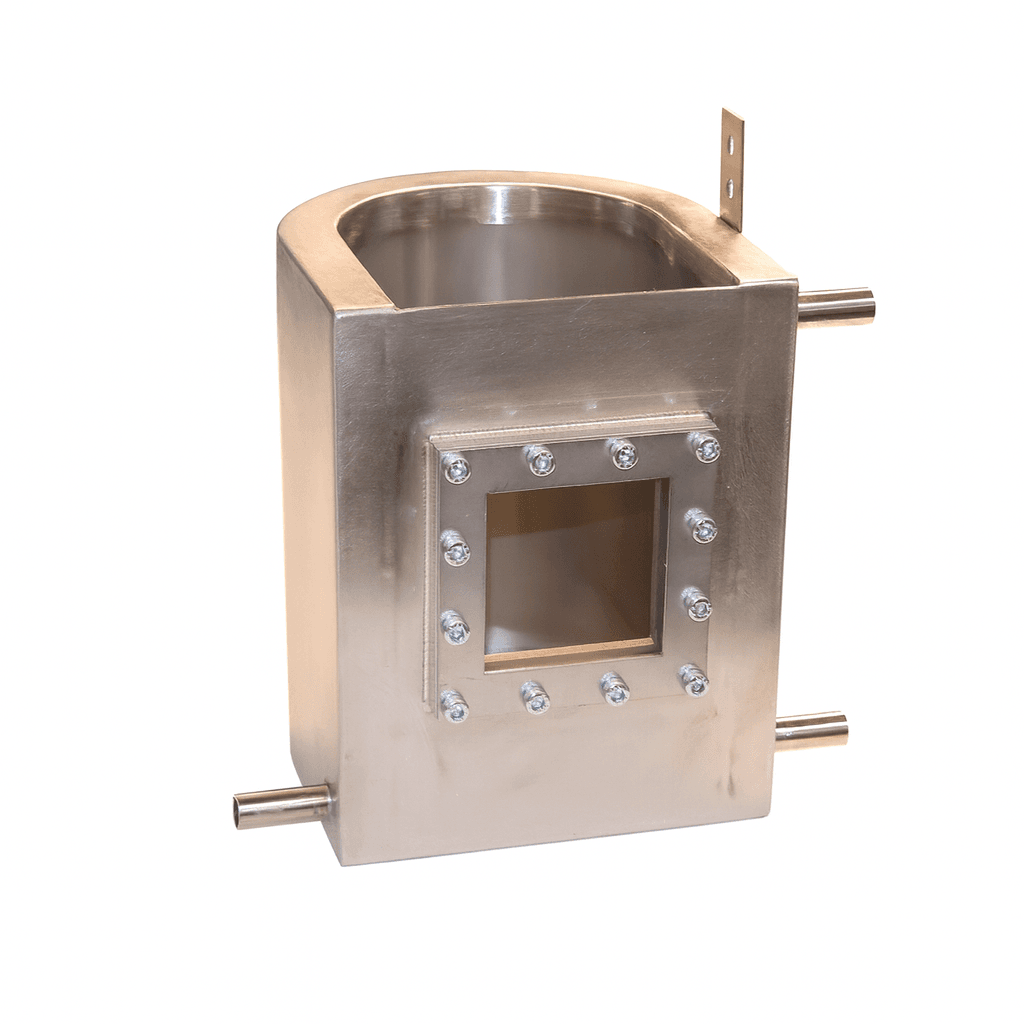

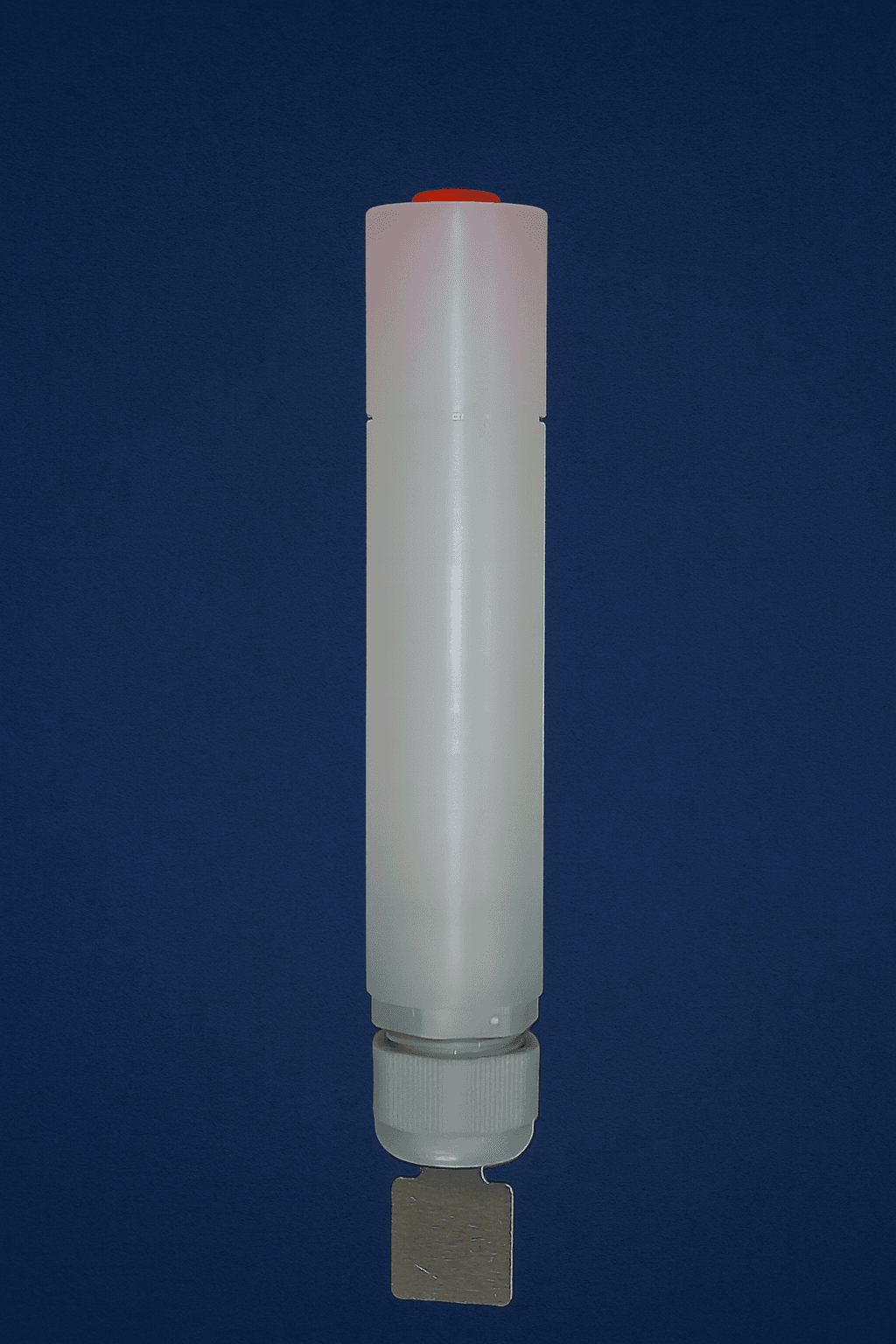

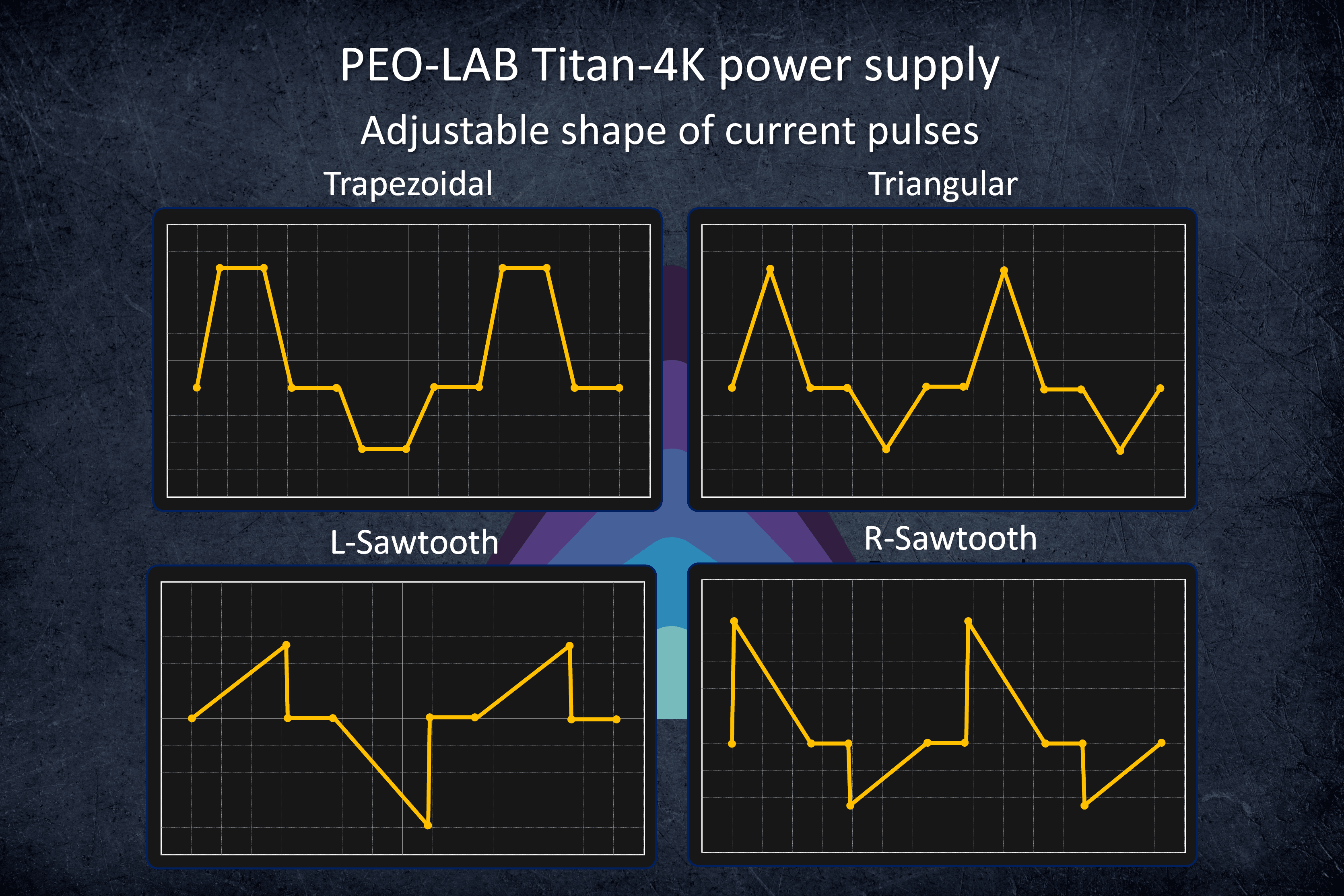

The kit includes a programmable power supply, a high-performance electrochemical PEO cell, a set of samples for initial training, and a dedicated specimen holder. The power supply features an advanced current pulse-shaping capabilities, an integrated process monitoring system, full control via a laptop using the CSM application and a compact, portable design suitable for on-demand operation. The included PEO cell is a jacketed reaction vessel equipped with a quartz viewport, enabling convenient visual observation, photography, and optical spectroscopy of the light emitted during PEO treatment.

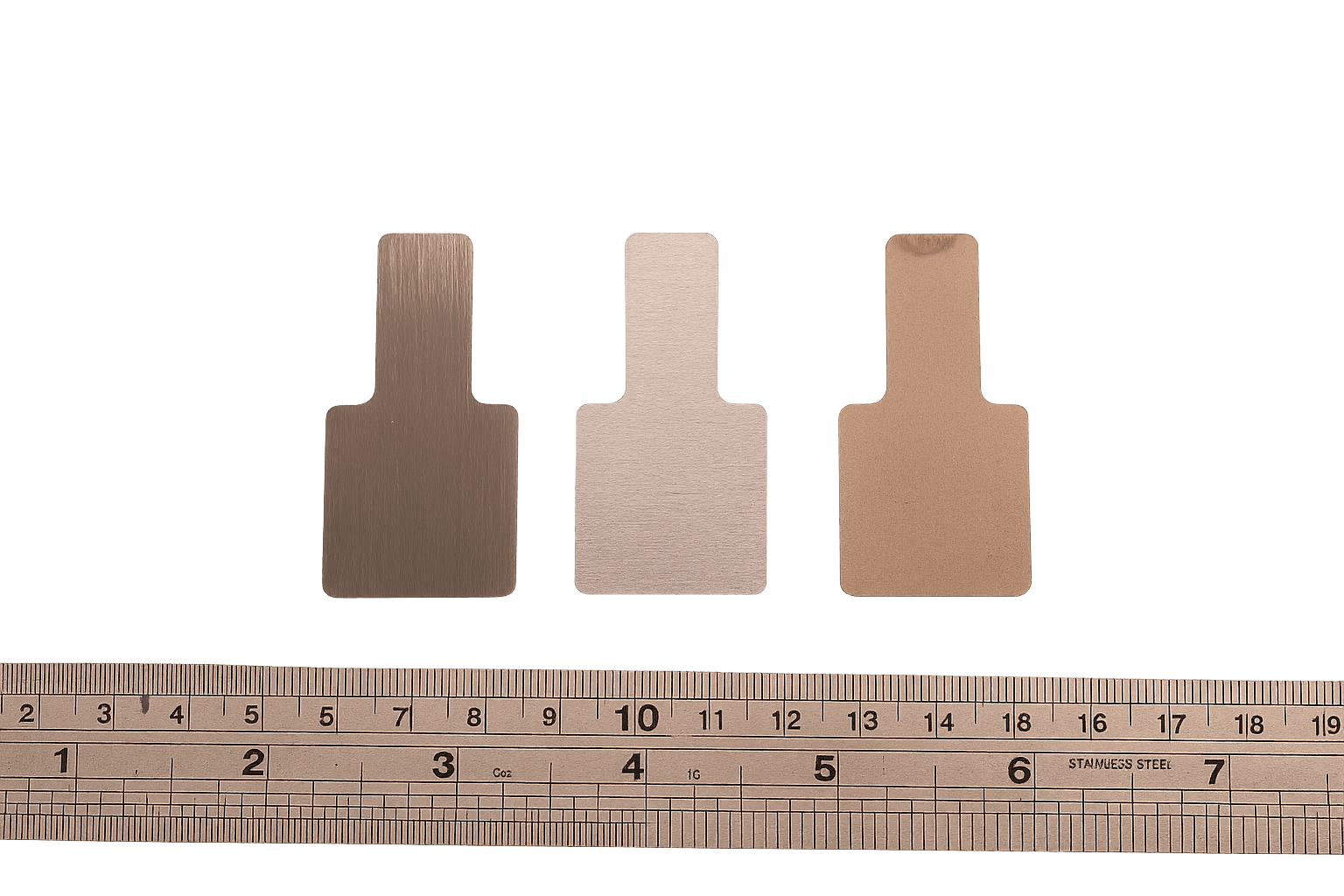

A starter set of commonly used alloys — AZ31B, A1050, and Ti Grade 2 — along with the specially designed specimen holder, allows users to perform initial tests, demonstrations, and hands-on training with minimal setup effort.

Price: On request

Specifications

Accessories

| Type | Plasma electrolitic oxidation |

General

| Weight / kg | Power supply: < 12 kg, 2L cell: 3 kg |

| Ambient temperature | +5 to +30 °C |

| Safety | Interlock protection |

| Kit includes | Titan-4K – lab scale PEO power supply (650Vpeak, 4A max), Stainless steel 2L jacketed cell with quartz viewport, Set of standard specimens (10 sq.cm) for Mg, Al and Ti (30 of each). Holder for standard specimens |

| Dimensions |

Request Quote / Info

Your request will be sent to PEO-LAB via email.