* All prices are orientative and may vary depending on distributors, countries, and market conditions.

Description

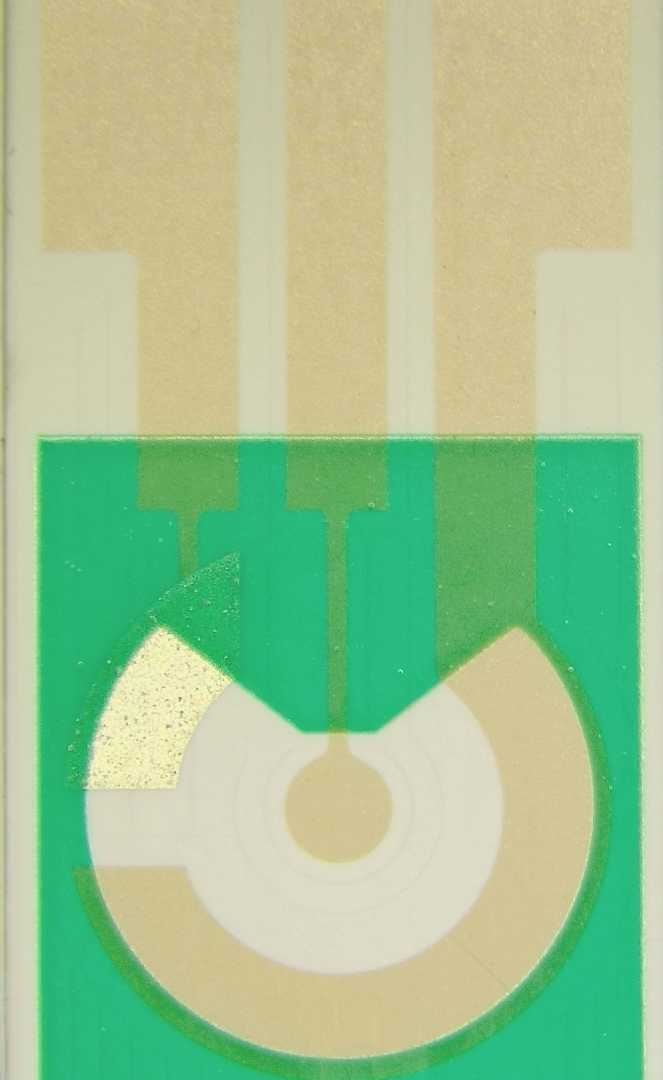

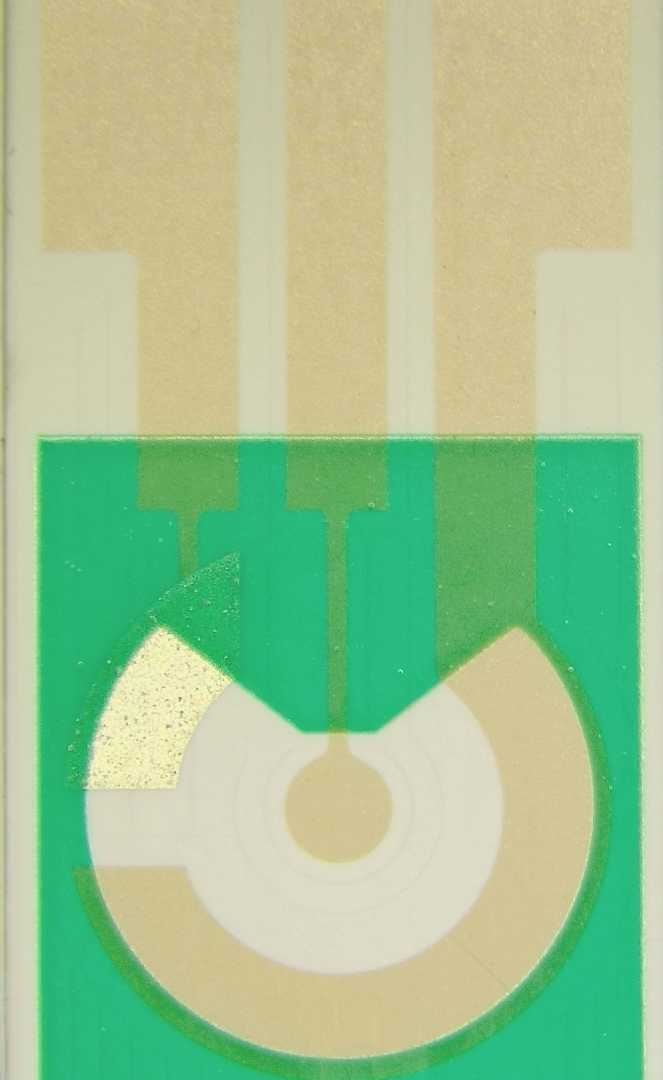

Gold electrodes are among the most widely used electrochemical biosensor substrates due to their ability to be easily functionalized with thiolated biomolecules. In recent years, various alternative fabrication methods have emerged to simplify production and reduce costs. These methods include screen printing and physical fabrication using commonly available materials, making them highly suitable for biosensor applications.

Gold screen-printed electrodes (SPEs) provide a cost-effective alternative to traditional cleanroom-fabricated platforms. The screen-printing process involves depositing metal ink onto a substrate through a patterned mask, which defines the electrode’s shape. This technique is advantageous because it accommodates a wide range of substrate materials, including plastics, polymers, ceramics, and paper, while allowing for flexible electrode design.

SPEs are highly reproducible and can be mass-produced efficiently. Their surfaces can be functionalized to create immuno-, genetic-, and enzymatic sensors, highlighting their versatility for biosensor development. Additionally, by modifying the composition of the gold ink, the surface morphology and roughness of the electrodes can be tailored, further expanding their potential applications in electrochemical sensing.

Price: On request

Specifications

General

| Applications | Biosensing |

General Electrode

| Electrode Type / Role | Miniaturized Electrochemical Platform |

Miniaturized Electrochemical Platforms

| WE Material | Gold (Au) |

| CE Material | Gold (Au) |

| RE Material | Ag/AgCl |

| WE Form |

Request Quote / Info

Your request will be sent to Selectoprobe via email.